Cutter Soil Mixing

The In Situ Soil Mixing technique, also known as Cutter Soil Mixing (CSM), had its technological principle

originated in USA, where in 1954 a screw type mixer was used to mix soil and cement. However this technology,

as it is presented today, was developed in Sweden and Japan.

The Cutter Soil Mixing(CSM) process consists of the construction (on site) of impermeable panels, with a geometry

much similar to a diaphragm wall.

The distinct difference between the Cutter Soil Mixing (CSM) System and other applications is that there is no soil

removed. This technique has tremendous cost savings in soil handling, and disposal. When working in a contaminated

area, the soil is neutralized by the addition of Portland cement or other chemical substances thus saving time and

money in transport and treatment at a hazardous treatment facility.

Goals

- Breakdown of soil structure;

- Soil and Cement mixing;

- Create a homogeneous structure consisting of soil and cement.

Applications

- Construction of cut-off walls for dams;

- Retaining walls;

- In Situ encapsulation of contaminated areas;

- Containment of adjacent structures.

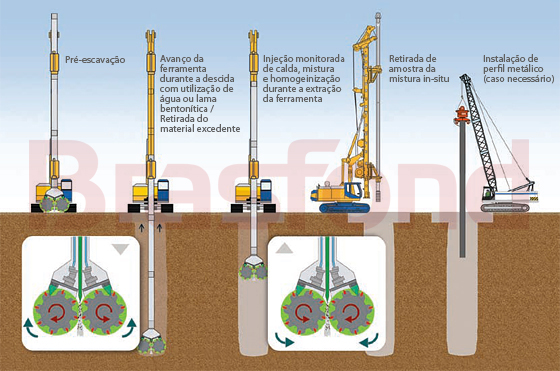

Execution methodology

Large diameter Bored Pile

Large diameter Bored Pile Slurry Wall

Slurry Wall Diaphragm Pile

Diaphragm Pile CFA Pile

CFA Pile Root Pilles

Root Pilles Jet Grouting

Jet Grouting Environmental Geotechnics

Environmental Geotechnics Soil improvement

Soil improvement Cutter Soil Mixing

Cutter Soil Mixing Hydromill

Hydromill Tiebacks

Tiebacks Massive treatment

Massive treatment Static load tests

Static load tests

Services

Services